urbansheep@gmail.com

Stronger-than-steel fibre spun from wood | KTH - http://www.kth.se/en...

|

11 июня 2014 в 10:02 с Bookmarklet

Taivo Lints

eugenio

Тринадцатый

9000

Michael Bravo

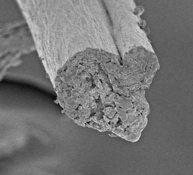

“We have taken out fibrils from natural cellulose fibres,” Lundell says. “Then we have assembled fibrils again into very strong filament. It is about 10 to 20 microns thick, much like a strand of hair.” ¶ The research offers potential for creating natural clothing textiles based on wood instead of cotton, or even replacing fiberglass in cars, trucks and boats. ¶ Lundell says that that unlike existing processes for making strands of cellulose, such as rayon, their composition process is environmentally friendly and sustainable. The only other ingredient in the process is sodium chloride – commonly known as table salt – for binding the fibrils together.” - × × ×

Древесина с солью [x] - × × ×

КО беспокоится о последствиях контакта с водой - Good command or file name

© 2015 FriendFeed (and Clio archiver)